Solid-state batteries, a promising technology never quite ready for commercialization, finally look like they are getting closer to reality.

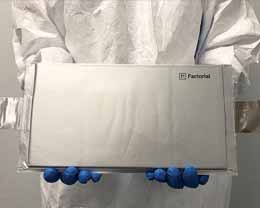

Many battery suppliers, including longtime heavyweight CATL and startups, are competing to get their solid-state batteries to market. At least two companies, Factorial Energy and QuantumScape, sent more-advanced samples to customers’ labs and test vehicles last month.

Factorial Energy and Stellantis said they will test Factorial’s semisolid-state batteries in Dodge Charger Daytona demo vehicles on public roads in 2026.

QuantumScape said it sent solid-state battery samples to Volkswagen-backed PowerCo for testing and validation.

“It is a significant step on the road to commercialization,” said Conrad Layson, senior alternative propulsion analyst at AutoForecast Solutions.

Samples at this stage, called B samples, “are the first solid look at a prototype battery on the way to commercialization.”

Performance metric

The samples now provide automakers with a form factor that can be part of a vehicle design, and a measurable performance metric, Layson said.

Once Factorial’s battery reaches Stellantis’ standards in the Charger, the company can scale the technology across its brands, Anne Laliron, senior vice president and head of technology research for Stellantis, told Automotive News.

Dodge, Jeep, Chrysler, Maserati and Alfa Romeo use a similar EV platform designed to support up to 2 million vehicles globally. Stellantis’ collaboration with Factorial leverages its $75 million investment in the battery startup in 2021.

QuantumScape is also advancing its all-solidstate battery development. The company said it has begun producing low volumes of its first B sample cells and shipped them to PowerCo for testing.

Both semisolid- and solid-state battery technologies are potentially safer than the lithium ion batteries in today’s EVs because they eliminate or reduce flammable liquid electrolyte. They also have more energy density, which can lead to longer ranges and faster charging times than today’s EVs.

Solid-state batteries with no liquid or gel are the ultimate goal of most of the industry. Quantum- Scape says it is developing a fully solid electrolyte.

The company believes the safety and energy benefits of all-solid-state batteries give solid-state cells an advantage over semisolid-state batteries that have small amounts of liquid or gel — still far less than traditional lithium ion battery cells.

QuantumScape is transferring its battery technology to PowerCo, which intends to eventually produce the cells at scale. Testing these samples can take 12 to 18 months, said Will Hudson, QuantumScape’s vice president of product.

“The goal of this collaboration is to get these cells into customer vehicles, but it proceeds through a bunch of testing,” he said. “There will be pack testing that takes place outside of vehicles, and then there will be vehicle testing. And all that culminates in the larger-scale manufacturing to support sales of vehicles.”

‘Time to market’

Factorial is working on both semisolid-state and all-solid-state cells, but Stellantis is focusing on the technology that’s available today while keeping all-solid-state batteries on its road map.

One advantage to semisolid-state is the ability to use existing plants that make lithium ion batteries, Laliron said.

“We need to go into concrete experimentation of the chemistry. It doesn’t mean that all-solidstate is not interesting,” she said. “It’s a question of balance and also time to market. As soon as we have a good added value for the customer, we consider the chemistry.”

Stellantis and Factorial are testing the battery in a vehicle, rather than in a lab, to accelerate the validation process, she said.

“There is a big gap between validation at cell level in the lab and validating integrated into a car into a battery pack,” Laliron said. “That’s the purpose of this fleet … in order to accelerate the validation and to really anticipate any discovery that we would have while integrating into a battery pack and into a vehicle.”

The in-vehicle testing puts the batteries closer to commercialization. It is meant to validate the technology and test performance in real-world driving conditions. Stellantis will adjust the cell chemistry with Factorial based on the performance of the batteries in the demo vehicles.

Both Stellantis and Factorial need to ensure that many parts of the EV — the module, the pack, the battery management system — are validated with the battery, said Siyu Huang, CEO at Factorial Energy.

“Not until you have a real vehicle running on the street and being tested [in] a fleet size that we will know the consistency among the different vehicles,” she said. “This is definitely beyond what a typical demo car will look like, and it’s going to be in the real-world scenario and being driven by the typical drivers.”